Our Research

Since the production of insulin in microorganisms in 1978, bacteria have been utilized as mini-factories for making biotherapeutics from vaccines to cancer treatments. While biomanufacturing has revolutionized the treatment for many medical conditions, the access to many of these medications can be limited due to the immense cost in producing these life-saving medications. Our research focuses on optimizing a new secretion system for production of commercially important small peptides, including those used in diagnostic imaging and type 2 diabetes treatments. By inserting the genes for these proteins into a novel E. coli genetic construct, we can turn the bacteria into continuously producing mini-factories that will reduce manufacturing costs and make these life-saving proteins more accessible. Moving this system into the commercial biomanufacturing space requires us to have a deeper understanding of its capabilities, limits and optimal environmental conditions.

Our Strategy

Biomanufacturing researchers emerge from this stream with transferable skills that they can use throughout their careers. Through the practice of science, students will develop proficiency in critical power-skills such as oral and written communication, building on the ideas of others to create a novel synthesis, data analysis and interpretation, troubleshooting and resilience. All while experiencing the magic of scientific

research!

Biomanufacturing students will learn a variety of methods and technical skills including:

- sterile technique

- microbiology

- transformations

- molecular cloning

- spectrophotometry

- LCMS

- polyacrylamide gel electrophoresis

- western-blotting

- protein activity assays

- bioproduction

- fermentation

Our Impact

Biomaterials produced by bacteria are providing solutions to some of our world’s most pressing challenges. From reducing reliance on petroleum products to mitigate climate change or producing the next generation of biotherapeutics, biomanufacturing is providing an innovative way to address difficult problems. The most costly and time intensive parts of biomanufacturing are the isolation and purification processes for these biomaterials.

Our lab is working to optimize a novel secretion system for small-proteins developed by the Davies’ lab. If we can develop a system for secretion of these proteins in their functional form, it will drastically reduce the expense of bioproduction and make biotherapeutics more accessible and commercially viable.

We are grateful for support from our collaboration with:

Our Team

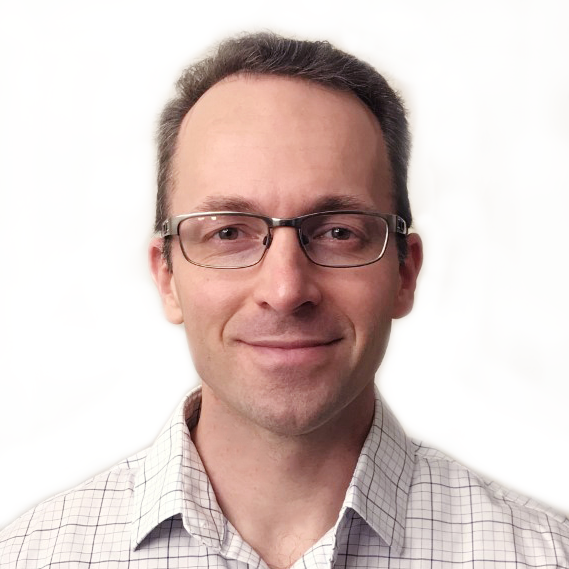

Bryan W. Davies

- Professor

- Lorene Morrow Kelley Professorship in Microbiology

- Molecular Biosciences

- Interdisciplinary Life Sciences Graduate Programs

Andrew Ellington

- Professor

- Molecular Biosciences

- Interdisciplinary Life Sciences Graduate Programs

Wilson M. and Kathryn Fraser Research Professorship in Biochemistry (Holder)

Katie Hansen

- Assistant Professor of Practice

- Freshman Research Initiative

- College of Natural Sciences

Research Educator | Biomanufacturing Stream